Our mission

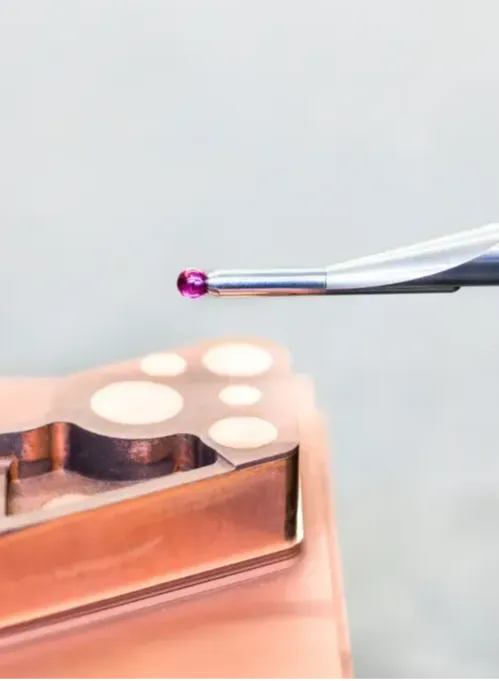

"Your Solution. A Part of Us." - this slogan represents our commitment to transform excellent multi-material expertise into value for our customers. With over 75 years of experience, we combine centralized development in Switzerland with an efficient best-cost production network in Europe and Asia.

As an international group with 500 employees, we produce around 25 million components and assemblies annually. Our solutions are found in the automotive, machinery, optics, electronics, furniture, and building automation industries.

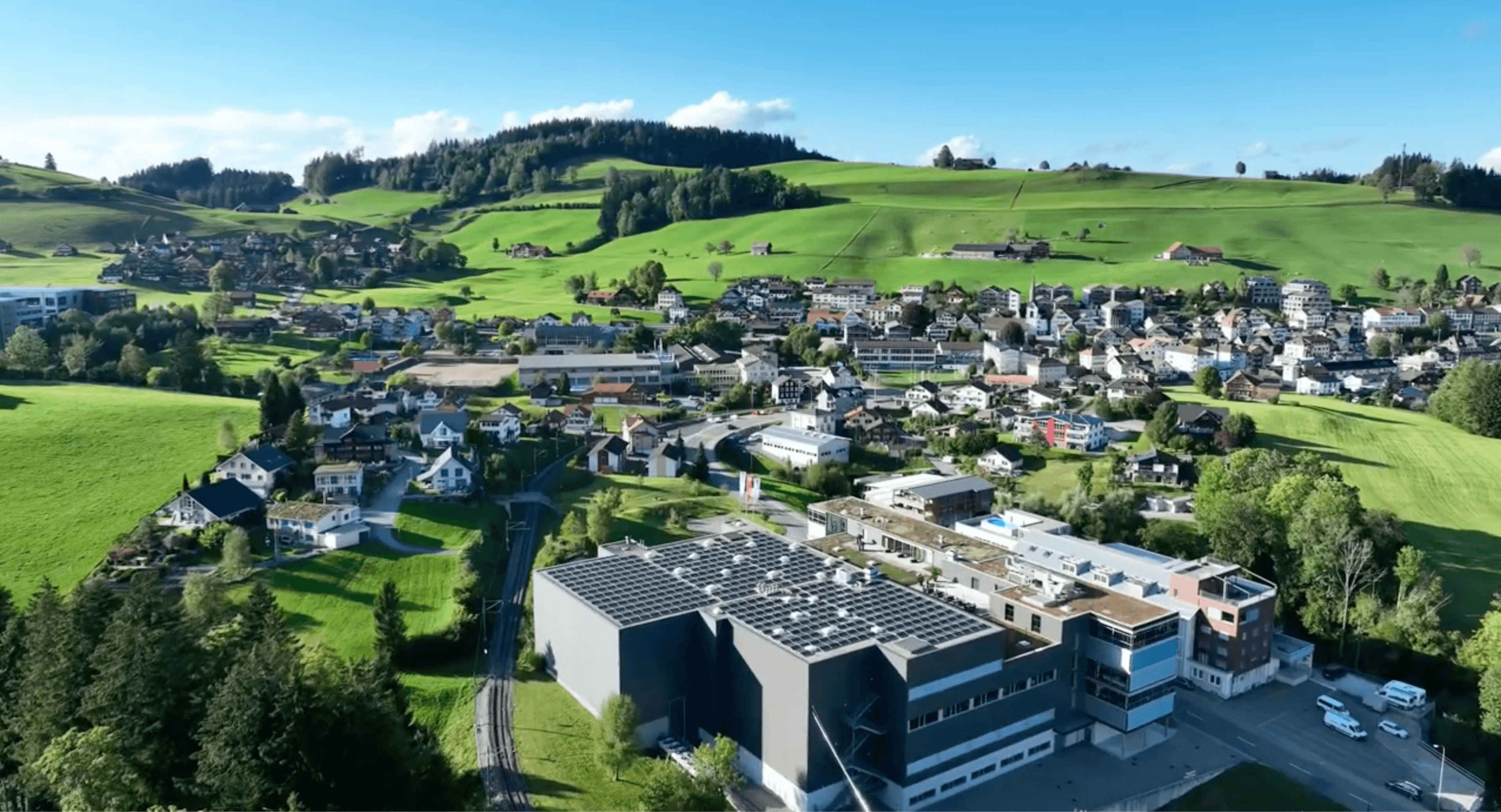

Locations

Contact Person

"As a third-generation family business, we focus on sustainable partnerships. Our international presence and focus on innovative, highly productive manufacturing solutions make us the long-term development and production partner for our customers."

"Based on our material-neutral and international orientation, we develop innovative solutions together with our customers. This allows us to reduce the total cost of ownership (TCO) for the customer."

"We realize complex hybrid solutions and function-tested assemblies with an innovative, motivated team, efficient processes and top machinery."

"As a solid and reliable partner, we aspire to communicate with our stakeholders in a timely, targeted and transparent manner."

"The broad range of solutions for a wide variety of customer product and process requirements is testament to our curiosity, customer focus and innovative spirit.

The interdisciplinary approach during the development phase is our critical success factor for achieving success in this exciting and challenging working environment."

"We offer you customized solutions that are free from material constraints and precisely tailored to your individual needs. Our focus is on seamless function integration, innovation, and creativity to provide you with an optimal solution."

‘My incentive is to develop customised solutions for you and to successfully realise your visions. Your success is my motivation.’

"A successful project is the result of a strong idea, a clear strategy and a team working together towards a common goal."

«Only the greatest challenges shape true success, for without obstacles and difficulties, the journey would not be as valuable and the achievements not as meaningful.»

"It is very important to me to fulfil customer requirements at all stages of the value chain."

"My aim is to provide our customers with satisfactory support, from the quotation to the order and until the delivery."

"Every employee is both a customer and a supplier. This mindset drives our commitment to excellence in quality and processes."

Ready for a new challenge?

Our dedicated employees are the key to our success. Through continuous education and training, we promote their development and ensure our competitiveness in an international environment.

Join our team! Apply directly here.

Our history that shapes our future

Wanger's success story

Founded in 1945, our SME from the Appenzell hinterland has developed into an important supplier for global corporations. Wagner AG has always been owned by the Halter family and is run as an owner-managed company. Our eventful history is characterised by innovation and tradition, which have made us a reliable partner.

Corporate and Social Responsibility

Environment & Social

Through material-optimized solutions, we significantly contribute to improving the CO2 footprint of our customers' products. Internally, employee safety and environmental protection are our top priorities. With our ISO 14001-certified environmental management system, we continuously improve our sustainability performance through targeted CO2 reduction and energy efficiency measures.

Social responsibility

As a family business with a long-term focus, we attach great importance to social responsibility. Our business relationships are based on respect and mutual trust. A clearly defined code of conduct governs co-operation within the company and with external partners.

News at Wagner

Our quality promise

More than a promise

Quality is the foundation of our actions. Through continuous improvement and consistent processes, we create solutions that meet the highest standards and generate sustainable value for our customers.

Stable and robust processes along the entire value chain are our trademark - through precise measurement methods and customized quality tools. Our certifications according to ISO 9001, IATF 16949 (Automotive), and ISO 14001 (Environment) confirm our high quality standards.

Quality that builds trust.